Is It Time to Rewrite Vessel Operability Specs for the Next Project?

In the high-stakes world of offshore operations, vessel operability is everything. It’s not just about whether the vessel can handle rough seas; it’s about ensuring safe transfers, secure station-keeping, and timely project execution—no matter what the ocean throws at you.

Traditionally, these operability specifications are defined using Response Amplitude Operators (RAOs), which predict a vessel’s response under various wave conditions. While RAOs have been a cornerstone of naval architecture for decades, the question is becoming louder by the day: Is this old-school method still the best we can do, or is it time to upgrade to a new paradigm in real-time vessel motion analysis?

1. How Vessel Operability Specs Are Currently Written Today?

a. Predictive Curves & Operational Envelopes

Naval architects run wave-basin tests or computational simulations to generate RAO curves. These curves describe the vessel’s expected motion—heave, roll, pitch, surge, sway, and yaw—across a range of wave heights, periods, and directions.

b. Design Conditions & Assumptions

RAOs hinge on the vessel’s “design condition”—ballast, cargo load, distribution, and sea-state assumptions that might be radically different from what happens in real-time.

This inherently static approach can lead to over-conservative or, in some cases, dangerously optimistic specifications.

c. Safety Margins

Because RAOs are theoretical models, large safety margins are often layered onto these specs.

While this is good for reducing risk, it can also shrink operational windows, causing project delays and lost revenue.

2. The Cracks in the RAO-Only Approach

a. Limited Adaptability

Vessels are dynamic systems—cargo changes, ballast configurations shift, and real sea conditions rarely match the average or “typical” scenarios used in model tests.

RAOs, while robust for initial design, may not capture the nuances of every operational configuration.

b. Inaccurate in Real-Time

Once the vessel leaves the design mode or when sea states deviate from the forecast, the RAO-based specs might be at odds with reality.

This can lead to premature operational stops or, worse, operations that proceed under inaccurate assumptions.

c. Reactive Decision-Making

Traditional RAOs give you a static picture. They do not inherently provide near-future predictions that could help the crew plan lifts, gangway transfers, or DP (dynamic positioning) tasks with a proactive mindset.

3. Why Now? New Technology & Data-Driven Insights

“In an era of Digital Twins, Real-Time Wave and Current measurements, and IoT-enabled sensors, depending solely on RAO-based specs can feel like using a paper map in a world with GPS.”

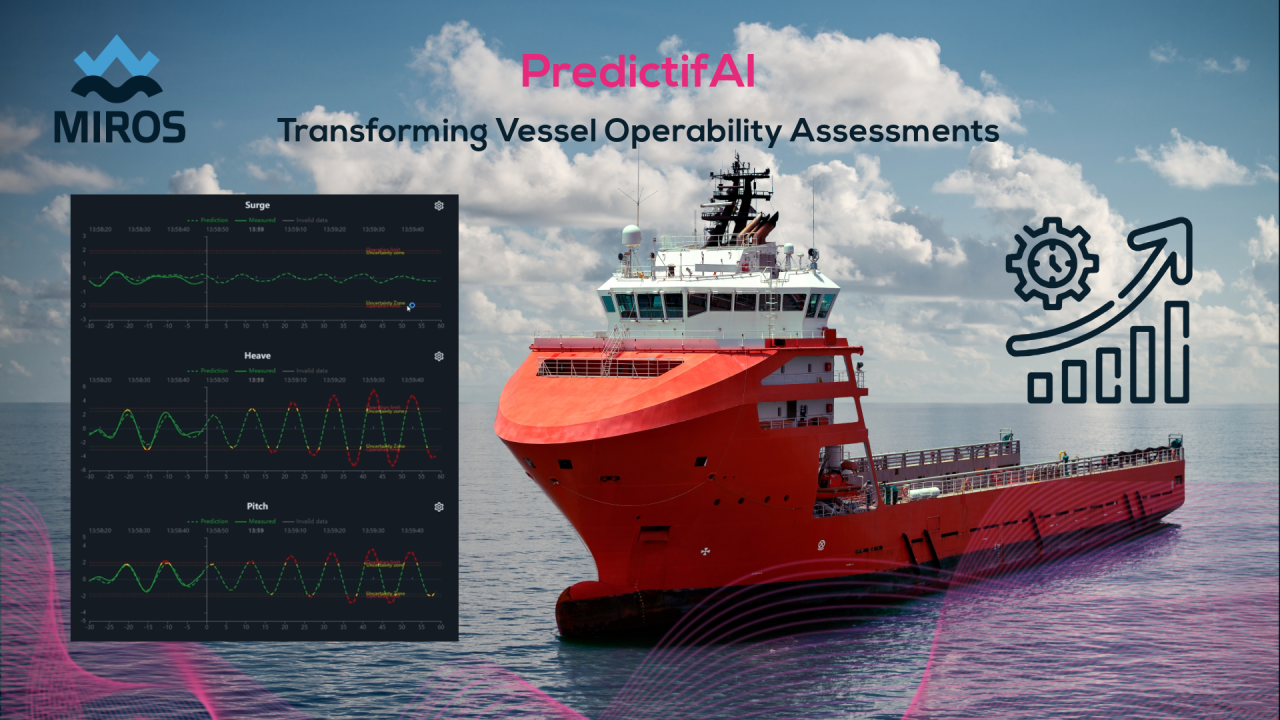

“Today’s real-time measurement systems—such as Miros’s PredictifAI®—capture actual sea conditions and vessel motion data, then run predictive analytics to forecast vessel behavior minutes into the future. This live lens on vessel performance doesn’t just match the static RAO approach—it has the power to radically transform and refine it.”

Real-Time Adaptation

Traditional RAOs give you a static picture. They do not inherently provide near-future predictions that could help the crew plan lifts, gangway transfers, or DP (dynamic positioning) tasks with a proactive mindset.

Dynamic Operability Envelopes

Instead of a single, static envelope, operators can work with dynamic operability specs that shift with changing wave states, heading, or vessel configuration, often extending operational windows safely.

Predictive Foresight

Forecasting wave impacts and vessel responses up to two minutes in advance is a game-changer for scheduling critical operations—like hooking up cargo or moving personnel—when the vessel is most stable.

4. Boosting Operational Windows & ROI

The key advantage of rewriting vessel operability specifications to incorporate live data is the expansion of safe operational windows:

- Less Excessive Conservatism: Traditional RAOs often force operators to plan around a worst-case scenario. Real-time data pinpoints actual stressors and motions, letting you push the envelope safely without overstepping.

- Reduced Downtime: Operators can execute tasks during favorable short-term weather “lulls” previously deemed too risky under static specs.

- Cost Savings & Project Efficiency: Every extra day at sea due to weather delays can cost millions. Live-based specs minimize these surprises, delivering significant ROI over a project’s lifespan.

5. A New Wave of Best Practices

If you’re planning the next generation of vessels or retrofitting existing ones, here’s a blueprint for rewriting your operability specifications:

- Combine RAOs & Live Data: Keep RAOs for broad design and safety case considerations, but overlay real-time measurements for day-to-day or hour-by-hour operations.

- Incorporate Predictive Analytics: Utilize short-term wave and motion forecasts (1–2 minutes ahead) to inform on-the-spot decisions regarding crane lifts, DP adjustments, or human transfers.

- Evolve the Safety Case: Reassess how you calculate margins, factoring in real-time data capability. This could lower overcautious boundaries while maintaining—or even enhancing—safety standards.

- Integrate Into Crew Training & SOPs: Make sure crews understand how to read and leverage real-time motion data. Rewrite standard operating procedures (SOPs) to include dynamic thresholds and predictive insights.

Conclusion: Time to Shake Up the Status Quo

Is it time to start rewriting vessel operability specifications for your next project? Absolutely. The age of static, model-based RAOs as your sole source of truth is giving way to a new world powered by live wave and vessel-response measurements. By combining the stability of proven RAO fundamentals with cutting-edge real-time analytics, operators can maximize safety, reduce downtime, and squeeze every drop of efficiency out of each voyage.

Don’t let your next project be bound by yesterday’s limitations—embrace the next wave of maritime innovation and rewrite your specifications to reflect the reality of data-driven, real-time vessel motion analysis. Your crew, your budget, and your project timeline will thank you.