Get the Alpha Factor: Waves, Work & Wider Weather Windows Offshore

Our Renewables lead, Robert Bates, speaks to a marine warranty surveyor about what exactly Alpha factor has to do with maximising uptime during offshore operations.

As a former offshore wind underwriter, Miros Renewables lead, Robert Bates, is well acquainted with the industry’s highest-ranking risks, as well as their respective costs. In fact, he discussed many of these issues during a recent webinar session. Continuing his exploration of the topic, Robert sat down for a socially-distanced chat with marine warranty surveyor, Charles Scott, of Scott Marine Consultants, about the battle against uncertainty during offshore operations and how Alpha factor plays a part.

How big of a problem is significant wave height (Hs) when approving offshore operations?

If you’ve planned appropriately and your forecasts are accurate, you can identify decreasing trends in Hs and find a weather window appropriate for the limits associated with your operation. Nevertheless, you can get into very academic situations where your limit is, for example, 1.5m Hs, and your weather forecast shows a predicted Hs of 1.55m (exceeding your limit by 5cm). If it’s two days until the next weather window opens up, do you really want to wait? If you knew that the waves you were actually experiencing were just 1.4m Hs it would make it much easier to make a sound judgement based on the available engineering.

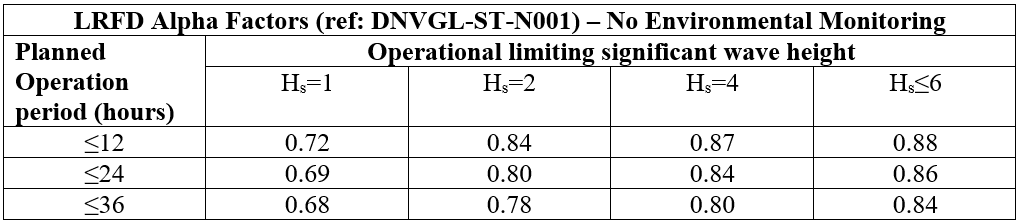

The DNV-GL guidelines (DNVGL-ST-N001) say that you need to look at the operation you are conducting and it’s sensitivity to the weather forecast. Based on that information, you can identify an Alpha Factor (the ratio between the operational limit and the design wave height) according to the duration of the operation and a range of other variables. Of course, it’s nice to have confidence that the weather forecasts you’re using are reliable, but if you’ve got a weather forecast saying one thing, and then you look at your sensors and they’re measuring something else, you might start questioning your confidence in the forecast.

Is an Alpha Factor often used in determining whether work can go ahead or not?

Yes, absolutely.

If we use a cable laying operation as an example, we’d do an analysis to work out what the design limit is for wave height. In this case, let’s say that our hypothetical vessel can install an array cable in up to 2m Hs, that’s our maximum allowable Hs, and above that limit there is a risk of something going wrong, such as damaging the cable. Theoretically, 2m is our limit, but we know that the forecasts aren’t always accurate, so we want to make sure we’ve got a bit of a margin, just in case the weather is higher than what the forecast is predicting. As a result of that desire to factor in uncertainty, DNV-GL conducted a joint-industry project looking at forecasted and observed wave heights, and came up with the Alpha Factors.

Let’s look at the guidelines.

So, back to our cable laying example. We said the design was for 2m Hs, and let’s say that the operation is going to take 12 hours. Looking at the table of Alpha Factors you can see that the operational limit is 2m x the Alpha Factor of 0.84. So that would then mean that our allowable forecasted wave height is 1.68m. You can see that the limit has already been reduced by quite a big margin to account for some uncertainty in weather forecast.

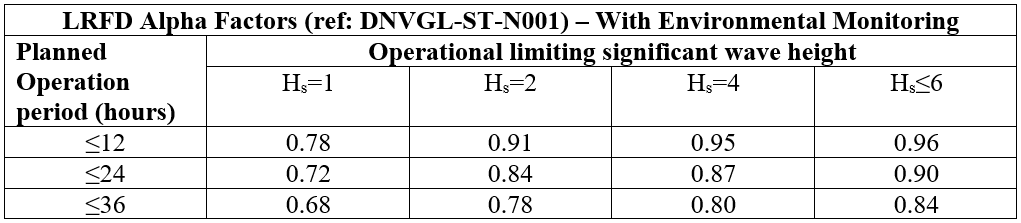

An Alpha factor relates to the sensitivity and duration of the planned operation, as well as the equipment or expertise that is in place, such as on-board environmental monitoring or an on-site meteorologist. Obviously, uncertainty about the reliability of the forecast increases the further into the future the forecasted conditions occur. For example, if it’s a 3-day operation, you’ve got to ask whether your weather forecast will be reliable by the time you get to the third day. The Alpha Factor would reflect that uncertainty.

For smaller wave heights, you tend to find much lower Alpha Factors. Looking at the table again, you can see that for a 12-hour operation and a design limit of 1m Hs, the Alpha Factor is 0.72, giving an allowable Hs of 0.72m, which reduces your operability by a relatively large amount!

However, let’s look at the next table, where the only difference is the addition of environmental monitoring, which could be one of Miros’ sensors, for example. Here, for our 12-hour 2m Hs cable laying operation, the limit has gone up from 1.68m to 1.82m. Our design limit has gone up by nearly 10%, and that’s the number we’ll assess against the weather forecasts when we want to start the operation. For operations that have larger allowable wave heights the absolute increase in allowable wave height when using environmental monitoring could be almost half a meter.

Does this mean that by simply having monitoring equipment onboard you can increase your limit?

In a lot of situations, yes. By having environmental monitoring equipment on board, you may be able to increase your operational limits and reduce risk. But there’s more to it than that. If we go back to our cable laying example, we have a 2m Hs design and, in theory, we don’t want to exceed that 2m because if we do, we could damage the cable and that could cause more issues further down the line – or worse, someone could get injured.

Let’s say some bad weather that wasn’t forecast comes through, or an updated weather forecast changes the outlook significantly, but we’re in the middle of our cable operation and it’s taking us over our allowable Hs. We would seriously have to ask ourselves what contingency measures we should put into action, where the worst case would be having to cut and abandon the cable. This is never a good situation and, after the fact, we’d want to go back and look at what the observed weather conditions were. Did the actual, observed weather exceed our forecast? Did we actually exceed the 2m Hs, and by how much? At this point, we’d go and look at the sensors, because a forecast is only a prediction, whereas the sensors measured what we experienced. So, did we see over 2m or not? If not, and we only saw 1.95m, nobody needs to worry. However, it might turn out we saw 2.5m and that’s when alarm bells start ringing because the cable could have been compromised. In this case, the contractor could run a dynamic cable analysis with the actual observed weather and confirm whether the cable could have been damaged or not.

Something I want to point out with the Alpha Factors, though, is that they don’t take wave period into consideration. Wave period can drastically reduce the operable wave height. For example, during something like a jacket installation, you might see limits of 3m Hs with a 5s period. But when that period increases to 6s, suddenly your Hs limit is just 2m. At 7s, it could be down to 1.25m. So, the impact can be huge.

Weather forecasts often only give wave period to the nearest second. So, let’s say that you’ve got a forecast that’s predicting a wave height of 2m and a 6s period. Are you confident that it is going to be 6s? Or is it going to be 6,5s? because that would have a big impact on your allowable limits. Having sensors onboard that can monitor wave period in real time would be very useful for managing this risk.

As far as a marine warranty surveyor is concerned, are there disputes over waiting on weather or standby charges?

Normally, the documented limits will be produced by the contractor based on their engineering, and these will be checked by both the marine warranty surveyor and the client prior to approval. The agreements take place before the work begins.

You need to have two independent sources for the forecasts, and you use the more conservative one to decide whether your operation should go ahead or not. What makes a big difference is the addition of environmental monitoring. If you’ve got that information, you can send it back to the meteorologist and ask whether the forecasts are agreeing with what’s being seen on site. After all, forecasts are only as good as the moment they are printed out.

It is worth noting that the marine warranty surveyor as an individual cannot stop the job if they are not happy with the weather forecast or what is being observed but they may choose not to issue their certificate of approval, which can be very influential on the decision of the contractor and client to start the operation or not. After all the marine warranty surveyor is only present to ensure the pre-agreed limits, upon which the engineering is based, are observed.

Are there any benefits you can see for a marine warranty surveyor in having sensors on a vessel?

It’s always nice to know what the actual weather you’re experiencing is. There have been times when we’ve had much bigger waves than were predicted and having local measurements would have been very useful. You rarely get the opportunity to see what the actual local conditions were and often forecasts cover a much larger area that doesn’t take into account local features such as sandbars, so you could very easily be missing weather windows because you’re being too conservative, or vice versa.

Having sensors on the actual vessel is definitely interesting. My knowledge of wave buoys is that they involve a lot of time for deployment and X-band radars for calibration and generally demand quite a lot of setup. This is also very expensive. As a result, you often don’t have many wave buoys nearby, and the closest available buoy could very well be in a location that is experiencing higher or lower wave heights than you are experiencing on location.

In any offshore situation, it’s better to have more information and better accuracy than not to have it, but at the end of the day, having informed decision makers with the relevant background knowledge who use it to make sound judgements is key. More and better information simply enables them to make their decisions with greater certainty.