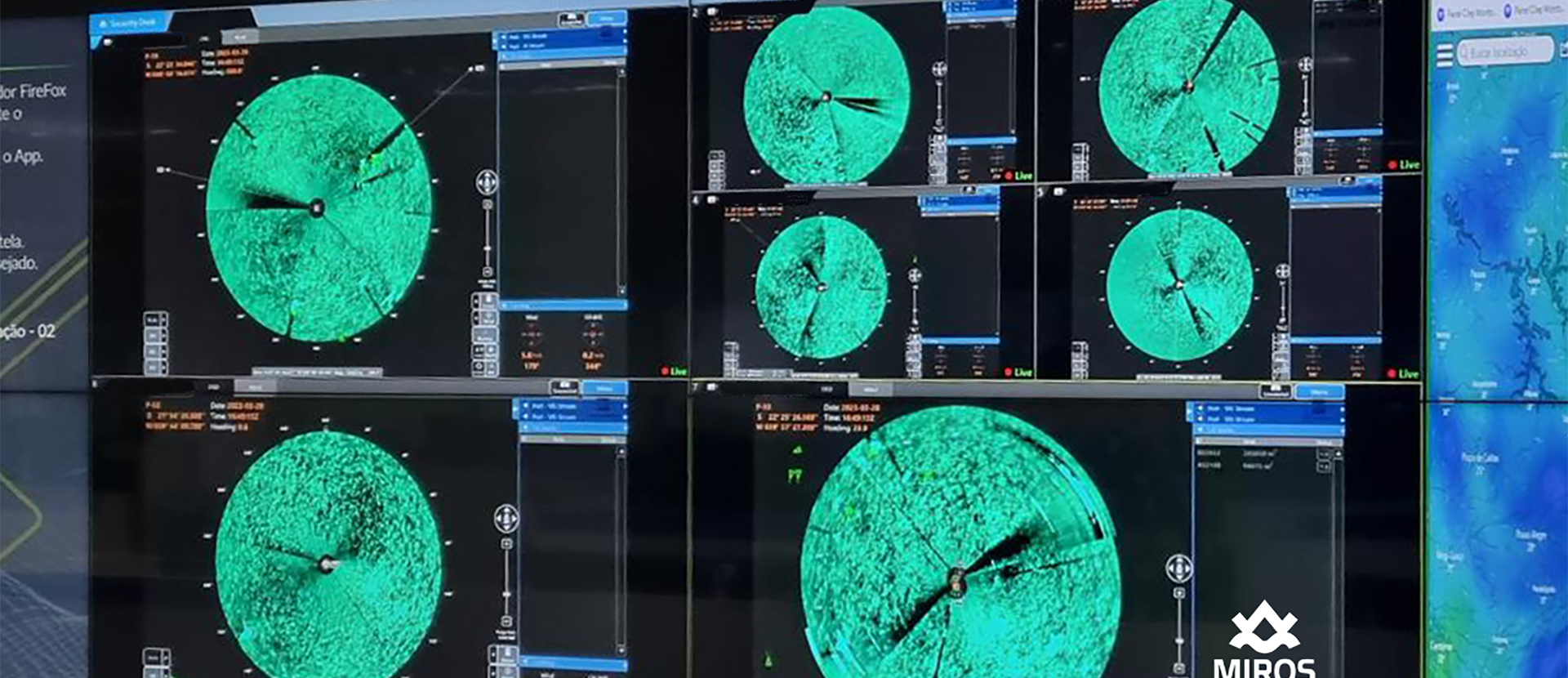

Oil Spill Detection

Early and reliable detection of an oil spill is vital. With more than 250 oil spill detection (OSD™) systems delivered to oil companies, ship owners and coastal agencies globally, Miros has established itself as a trusted provider of real-time systems for oil spill detection, also supporting response and surveillance operations.

Proven efficacy and low false alarm rate

Why Oil Spill Detection?

No need for manual intervention. The OSD can easily be switched to manual mode while guiding recovery operations.

Allows for more time to verify and characterize the spill and decide on the appropriate response.

High sensitivity & low false alarm rate. The Miros OSD system has a unique ability to interpret multiple indicators simultaneously, only triggering alarms when the “right” combination is identified.

Gives users the confidence that they are applying the best available technology to detect and control oil spills.

Data Analysts: Data Explorer is a great tool for data analysts who want to dive deep into their data and discover meaningful insights. With Data Explorer’s powerful querying and visualization features, you can quickly identify patterns and trends in your data that might otherwise be difficult to spot.

Operations teams: Can use Data Explorer to gain a better understanding of their operations and make data-driven decisions.

Site managers: With the ability to analyse data from multiple sources, Data Explorer can help site managers to identify opportunities for optimising their processes and reach their operational targets.

Who can benefit?